Liquid Crystal Display (LCD) technology has become a cornerstone of modern visual interfaces, from smartphones to TVs, and industrial equipment.

At the heart of this technology lies meticulous LCD panel design, which involves complex engineering and creative innovation.

In this article, we’ll explore the essentials of LCD panel design, its components, and how advancements continue to shape the display industry.

Key Takeaways

- LCD panel design is a multifaceted process that combines engineering precision with innovative technology.

- Advancements in resolution, energy efficiency, and materials are revolutionizing the field.

- Applications range from consumer electronics to industrial tools, showcasing the versatility of LCD panels.

What Is LCD Panel Design?

LCD panel design refers to the process of developing and optimizing liquid crystal display panels for various applications. It encompasses:

- The arrangement of liquid crystal molecules.

- The incorporation of backlighting systems.

- Integration with electronic circuits for signal processing.

By focusing on these aspects, designers ensure that the display delivers high-quality visuals, efficiency, and durability.

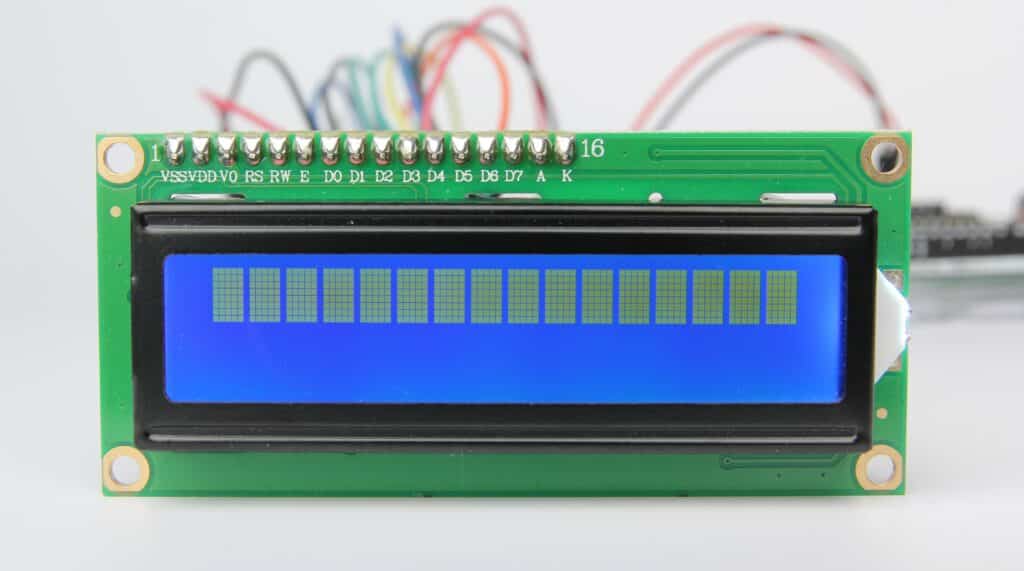

Key Components of an LCD Panel

Understanding the components of an LCD panel is fundamental to appreciating its design process:

- Liquid Crystal Layer: The core of the display, responsible for modulating light.

- Glass Substrates: Thin glass layers that enclose the liquid crystal layer.

- Electrodes: Conductive layers enabling voltage control over liquid crystals.

- Polarizers: Filter layers that control light orientation.

- Backlighting: A light source, often LED, to illuminate the display.

- Driver Electronics: Circuits that process and send signals to the display.

The Design Process

The process of designing an LCD panel involves several critical steps:

1. Requirement Analysis

Design begins with understanding application-specific needs such as:

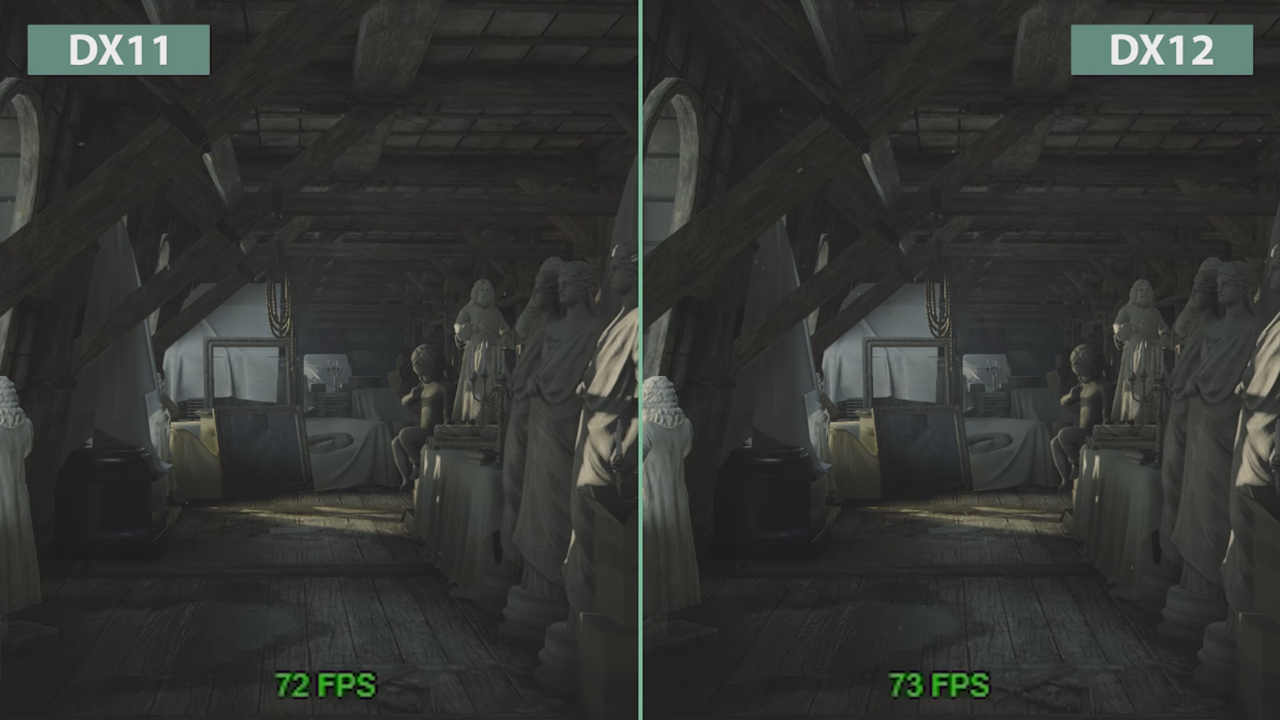

- Resolution: Determines pixel density.

- Refresh Rate: Influences display smoothness.

- Color Gamut: Defines color accuracy.

- Brightness Levels: Critical for visibility under various conditions.

2. Material Selection

Selecting high-quality materials ensures durability and performance. Advanced technologies now enable the use of:

- Flexible substrates for foldable displays.

- Low-power materials to enhance energy efficiency.

3. Simulation and Prototyping

Engineers utilize simulation tools to predict performance and resolve design challenges. Prototyping ensures:

- Accurate alignment of components.

- Verification of light transmission and color accuracy.

4. Testing and Refinement

Extensive testing validates the panel against parameters like:

- Temperature resilience.

- Power consumption.

- Viewing angles.

Advancements in LCD Panel Design

1. High-Resolution Panels

With the advent of 4K and 8K displays, pixel density has reached unprecedented levels. This trend benefits applications in:

- Gaming monitors.

- Professional-grade editing screens.

- Immersive entertainment systems.

2. Energy-Efficient Backlighting

Modern LCD panel designs incorporate LED backlighting systems that:

- Reduce power consumption.

- Enhance brightness and color uniformity.

3. Flexible and Foldable Displays

The integration of flexible materials enables:

- Foldable smartphones.

- Curved monitors for immersive experiences.

4. Improved Viewing Angles

Advanced technologies like IPS (In-Plane Switching) panels offer better:

- Color consistency.

- Viewing experiences from multiple angles.

Challenges in LCD Panel Design

Despite advancements, LCD panel design faces significant challenges:

- Cost Optimization: Balancing performance with affordability.

- Heat Management: Preventing overheating in compact designs.

- Durability: Ensuring longevity, especially in outdoor environments.

- Sustainability: Reducing environmental impact during manufacturing.

Applications of LCD Panels

LCD panels have diverse applications, including:

- Consumer Electronics:

- Smartphones.

- Tablets.

- TVs.

- Medical Equipment:

- Patient monitors.

- Diagnostic tools.

- Industrial Displays:

- Machine interfaces.

- Control panels.

- Automotive Industry:

- Dashboard displays.

- Rearview monitors.

The Future of LCD Panel Design

Looking ahead, LCD panel design is set to benefit from:

- Quantum Dot Technology: Enhancing brightness and color accuracy.

- Mini-LED Backlighting: Offering finer control over brightness zones.

- Integration with AI: Optimizing design and real-time performance adjustments.

FAQs

Q1: What is the lifespan of an LCD panel?

Most LCD panels last between 30,000 to 60,000 hours, depending on usage and maintenance.

Q2: How does LCD compare to OLED in terms of design?

LCD panels are more affordable and durable, while OLED panels provide better contrast and color accuracy.

Q3: What role does backlighting play in LCD design?

Backlighting illuminates the display, significantly impacting brightness and energy efficiency.

Final Thoughts

LCD panel design continues to evolve, driven by technological innovation and diverse application demands. By focusing on performance, efficiency, and durability, designers are paving the way for next-generation displays.

Whether for smartphones or industrial machines, LCD panels remain indispensable in the visual technology landscape. For more LCD related information check the globalleds.